How Does Metal Recycling Work?

At Rescued Metals & Equipment, we believe in giving metal a second life. Whether it’s an old appliance, a pile of scrap, or decommissioned industrial machinery, metal can be repurposed and reused through a fascinating and highly efficient process. And through that recycling process, we save metal from the landfill and create high-quality metals at a low cost. But if you’re not familiar with metal recycling, you might be wondering: how, exactly, does metal recycling work? Today, we’re exploring how metal recycling works and how surplus metal suppliers create high-quality metal.

1. Collection and Sorting

The process begins when individuals and businesses bring their scrap metal to facilities like ours. These materials can include everything from copper wire and steel beams to aluminum cans and car parts. Once the scrap is collected, it’s sorted by type. Ferrous metals (which contain iron, like steel) are separated from non-ferrous metals (like copper, brass, and aluminum). This step is crucial, as different metals have different recycling processes and end uses.

At Rescued Metals, we use a combination of magnets, sensors, and visual inspection to efficiently sort metals. Separating metals properly ensures higher-quality recycled material and helps prevent contamination that could make the metal harder to reuse.

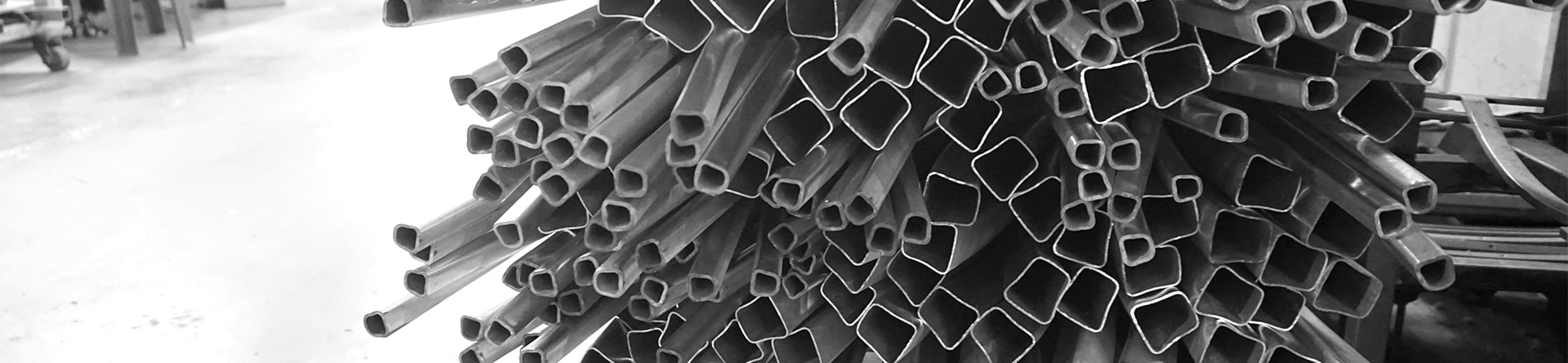

2. Processing and Shredding

After sorting, the metal is cleaned to remove any impurities such as paint, insulation, or oils. Then, it’s sent through powerful shredders that break it down into smaller, manageable pieces. Shredding is important because smaller pieces melt faster and more evenly, reducing the energy needed during the next phase.

This is where Rescued Metals shines. Because we also handle decommissioned equipment and larger metal parts, we’re equipped to process bulky or industrial-grade scrap that many smaller facilities can’t accommodate.

3. Melting and Purification

Next, the shredded metal pieces are melted in large furnaces specifically designed for each type of metal. Melting can take anywhere from a few minutes to several hours, depending on the volume and type of material. The energy used in this process is significantly less than that required to produce new metal from raw ore—making recycling a more sustainable option.

To ensure the metal is high quality, it’s purified through various methods, such as electrolysis or using powerful magnets to remove leftover contaminants.

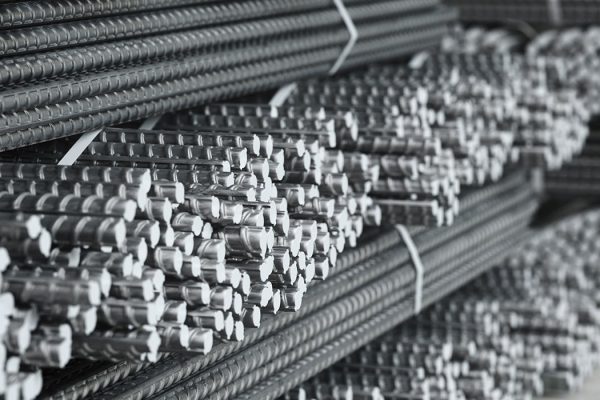

4. Solidifying and Repurposing

Once purified, the molten metal is poured into molds to form bars, sheets, or other shapes depending on its intended future use. These metal forms are then cooled and shipped to manufacturers who use them to make everything from construction materials and car parts to electronics and tools.

Recycling for the Future

At Rescued Metals & Equipment, we’re proud to be part of the cycle that keeps valuable resources in use and out of landfills. By recycling metal, you’re not only putting money in your pocket—you’re also helping the environment, reducing waste, and supporting sustainable industry. For more information on our recycling your metals or getting high quality recycled metals, click here to contact us today!